Features of Tube Ice Machine:

| Name | Technical Data | Name | Technical Data |

| Ice production | 5ton/day | Cooling mode | Air cooled |

| Refrigeration capacity | 35KW | Standard Power | 3P-380V-50Hz |

| Evaporating temp. | -15℃ | Ice tube diameter | Φ22mm/28mm/35mm |

| Condensing Temp. | 40℃ | Ice length | 30 ~ 45MM |

| Total Power | 25.2kw | tube ice weight density | 500~550kg/m3 |

| Compressor Power | 22KW | Evaporator type | Stainless steel seamless steel pipe |

| Ice cutter Power | 0.75KW | Ice tube material | SUS304 stainless steel |

| Water pump Power | 0.75KW | Water tank material | SUS304 stainless steel |

| Air cooled power | 1.65KW | Ice cutting blade material | SUS304 stainless steel |

| Net weight | 3210kg | Dimension of tube ice machine | 1900*1000*2080mm |

| Refrigerant | R404A/R22 | Dimension of air cooled condenser | 2646*1175*1260mm |

| Item | Name of Components | Brand Name | Original Country |

| 1 | Compressor | BITZER | Germany |

| 2 | Ice Maker Evaporator | ICESNOW | China |

| 3 | air cooled condenser | ICESNOW | |

| 4 | Refrigeration components | DANFOSS/CASTAL | Denmark/Italy |

| 5 | PLC Program control | SIEMENS | Germany |

| 6 | Electrical components | LG (LS) | South Korea |

The company has a construction team with extensive overseas installation experience, and they have bulit more than 50 large-scale projects worldwide.1. Installing by the user: we will tested and install well the machine before shipment, all necessary spare parts, operation manual and CD are provided to guide the installation. 2. Installing by our engineers: (1) We can send our engineer to assist the installation and provide technical support and train your workers. The end-user provides accommodation and round-trip ticket for our engineer. (2) Before our engineer arrived in your site, the installation place, electricity, water and installation tools should be ready. Meanwhile, we will provide you a Tool List with the machine when delivery. (3) All spare parts are provided according to our standard. During installation period, any shortage of parts due to the actual installation site, the buyer is required to afford the cost, such as water pipes. (4) 1~ 2 workers are required to assist the installation for big project.

The company has a construction team with extensive overseas installation experience, and they have bulit more than 50 large-scale projects worldwide.1. Installing by the user: we will tested and install well the machine before shipment, all necessary spare parts, operation manual and CD are provided to guide the installation. 2. Installing by our engineers: (1) We can send our engineer to assist the installation and provide technical support and train your workers. The end-user provides accommodation and round-trip ticket for our engineer. (2) Before our engineer arrived in your site, the installation place, electricity, water and installation tools should be ready. Meanwhile, we will provide you a Tool List with the machine when delivery. (3) All spare parts are provided according to our standard. During installation period, any shortage of parts due to the actual installation site, the buyer is required to afford the cost, such as water pipes. (4) 1~ 2 workers are required to assist the installation for big project.Technical data of tube ice machine

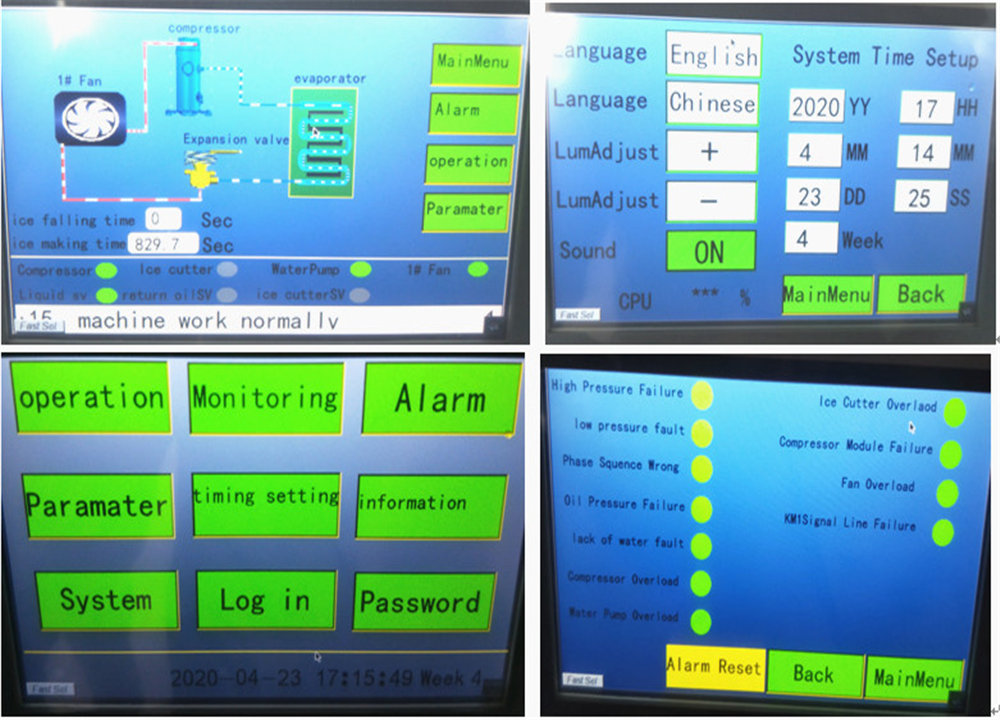

Interactive intelligent control system with touch-screen:

Advantages:

Our Partner

Our Service